| Characteristics of Acrylic Sheet |

- Beautiful, texture like a crystal, a "plastic queen" reputation - high transmittance, up to 92%, the most transparent plastic - excellent weather resistance, superior to other polymer materials - good colorability, high gloss | - High surface hardness, rich texture - Light, only half the weight of the glass - Good machinability, suitable for both machining and thermoforming - Good chemical resistance | - Good electrical insulation - Decorative, suitable for spraying, silk screen, vacuum coating, foil and other surface decoration - Comprehensive performance, very wide range of applications |

| Types of acrylic sheets |

| Ordinary plate | Transparent plate, dyeing transparent plate, milky white board, color plate |

| Special board | Bathroom board, blue and white board, red and white board, folder board, anti-red board, black and white board (photochromic), special plate, surface pattern board, frosted board, metal effect plate, optical grade acrylic plate |

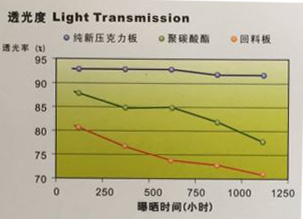

| Performance comparison between the new material plate and the return plate |

| Pure acrylic sheet of new materials | Return to the plate |

| *Anti-ultraviolet performance, at least 5 years without changing yellow, will not fade away light | *Anti-ultraviolet performance is very poor, very easy to yellowing, fading and cracking |

| *Transmittance greater than 92% | *Transmittance less than 80% |

| *Transparent colorless cross-section, processing (heat) to maintain good | *Yellow cross-section, although the brightener treatment of the material back to the plate, the initial yellowing to reduce, but after the short-term use of yellowing |

| *odorless | *In the process of heating, aggravated yellowing, and produce irritating odor, easy to crack |

| *Anti-cracking and anti-chemical properties | *Anti-solvent and chemical poor, easy to crack |

| *Good weather resistance | *Weatherability is poor |

| *High-quality protective film to provide adequate protection | *Packaging and protective film grade difference |

| Simple identification of the back plate |

1, look: Return to the appearance of yellow, from the cross-section is particularly evident 2, touch: easy to scratch the surface 3, smell: when the material back to the storage plate irritating taste strong, when cutting to stimulate the smell, smell when burning, blistering, emitting black smoke 4, thermoforming process prone to deformation, resulting in air bubbles | 5, the paint and ink-sensitive, prone to crack or crack 6, sunlight, easy to turn yellow 7, poor solvent resistance, easy to crack |

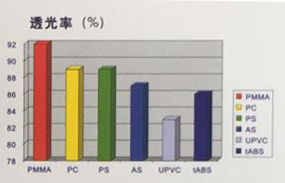

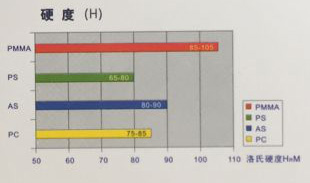

| And other materials comprehensive performance comparison |

| PMMA | PC | PS | PETG | ABS | PVC | |

| Anti-UV properties | excellent | general | difference | general | difference | difference |

| Impact resistance | general | excellent | difference | good | excellent | good |

| Processing performance | good | difference | good | difference | good | good |

| Resistance to chemical corrosion | good | difference | general | good | general | good |

| Scratch resistance | excellent | general | good | general | difference | difference |

| Optical properties | excellent | good | general | general | difference | difference |

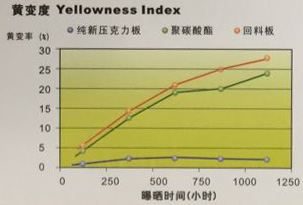

| Weathering test comparison (QUV 1000 hours) |

| Transmittance and hardness |